ASPICE

Note: The images in this document were generated using AI.

Concept

Automotive SPICE (ASPICE) is a framework for evaluating and improving software development processes in the automotive industry.

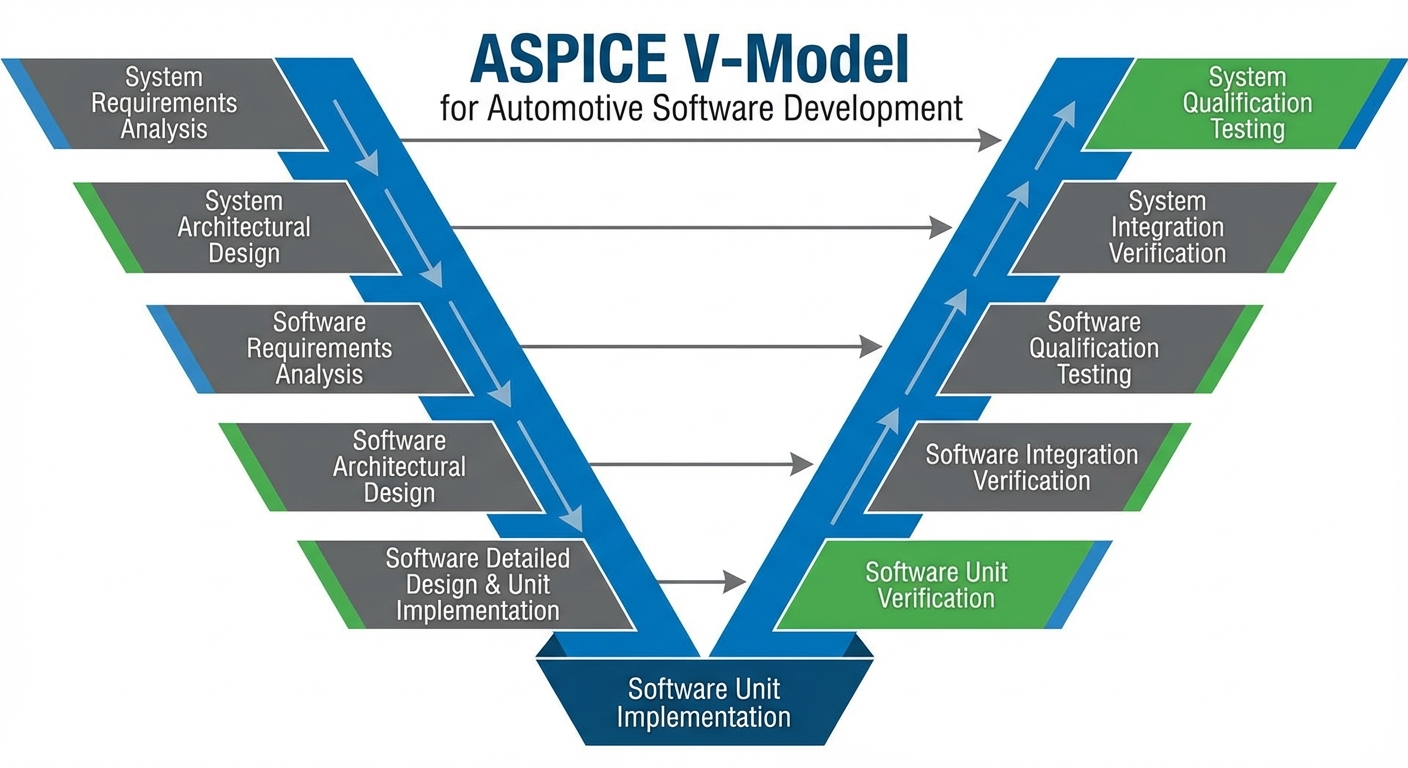

It is based on the V-model, which visually represents the development lifecycle.

The V-model connects development stages such as requirements, design, implementation, and testing, emphasizing rigorous evaluation and verification at each step.

This approach helps identify and resolve issues in the early stages of development, thereby improving the overall quality and safety of the software.

Key Summary

- Systematic Development based on V-Model: ASPICE systematically manages all stages of development from requirements analysis to testing through the V-model.

This is crucial for ensuring quality from the beginning of development. - Integration of Requirements, Design, and Test: The ASPICE V-model provides a comprehensive process covering System and Software Requirements Analysis, Architectural and Detailed Design, and Unit, Integration, and System Verification Tests.

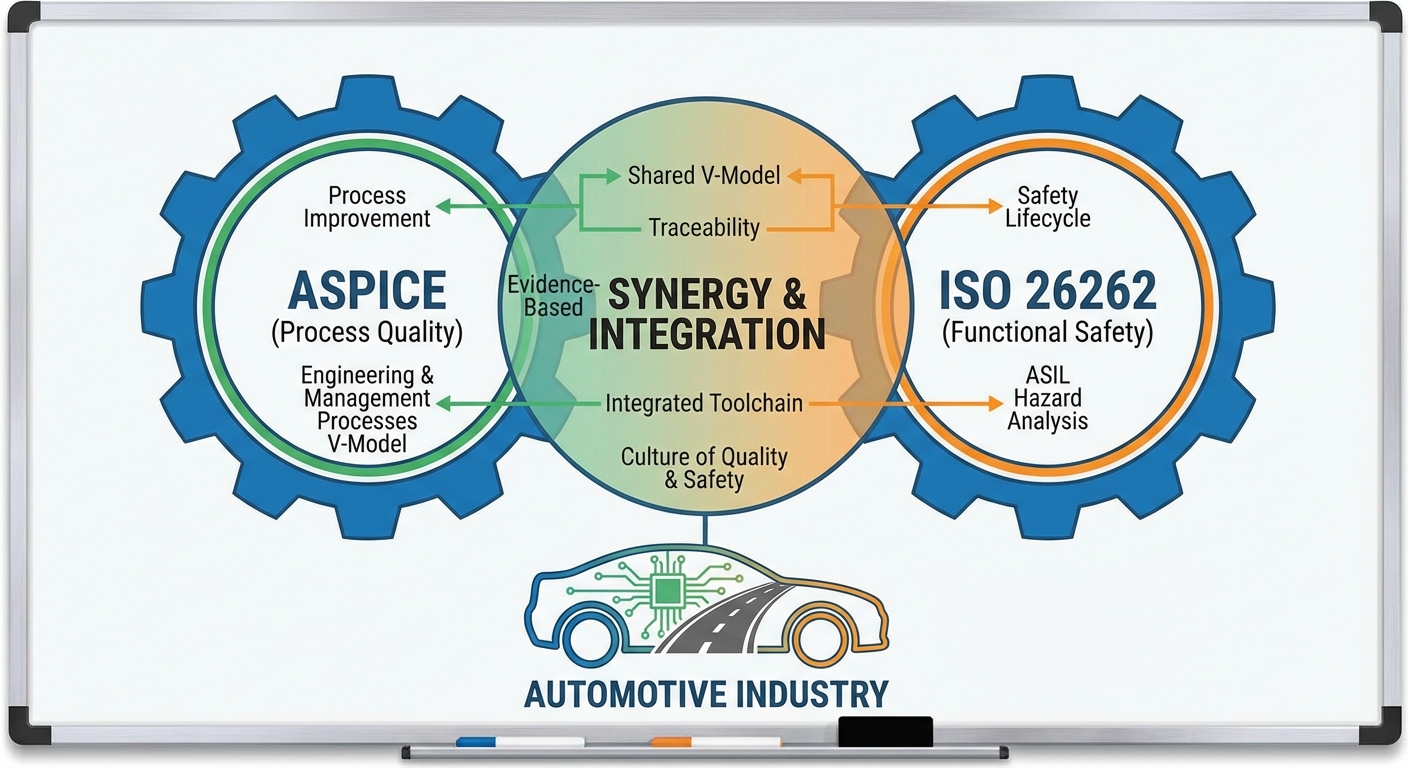

Each development phase has a corresponding test phase, enabling continuous verification. - Alignment with Functional Safety (ISO 26262):: ASPICE provides a robust framework for integrating functional safety standards like ISO 26262 into the project lifecycle.

While ASPICE focuses on process quality, ISO 26262 focuses on reducing risks due to malfunctions in electrical/electronic systems.

For critical automotive systems, complying with both standards is considered best practice.

Detailed Explanation

Understanding ASPICE and the V-Model

ASPICE is a standard for quality and process improvement in automotive software development.

The V-model visualizes the development process, showing how each stage of development is interconnected and verified.

The left side of the model represents requirements decomposition and design, while the right side represents integration and verification activities.

Detailed Core Processes

- Requirements:

- System Requirements Analysis: Defines requirements for the entire system.

- Software Requirements Analysis: Specifies software functionalities and constraints based on system requirements.

- The V-model necessitates a logical breakdown of these requirements.

- Architecture Design:

- System Architectural Design: Defines the high-level structure of the system.

- Software Architectural Design: Details software components and their interactions.

- Software Detailed Design: Specifies the internal design of each software module.

- Test:

- Software Unit Verification: Tests individual software units or modules.

- Software Integration Test: Verifies interfaces and interactions between integrated software units.

- Software Qualification Test: Validates the software against specified software requirements.

- System Integration Test: Tests the completely integrated system.

- System Qualification Test: Validates the system against specified system requirements.

Functional Safety and ISO 26262

Functional safety in the automotive sector is governed by standards such as ISO 26262.

ISO 26262 focuses on ensuring the absence of unreasonable risk due to malfunctioning electrical or electronic systems in road vehicles.

ASPICE provides a robust framework to integrate functional safety requirements into the project lifecycle.

While ASPICE focuses on overall process improvement and quality, ISO 26262 is specialized in functional safety aspects.

Therefore, for critical automotive systems, complying with both ASPICE and ISO 26262 is the best way to ensure both process quality and safety.

ASPICE Capability Levels

ASPICE defines six capability levels (0 to 5) to assess the maturity of organizational processes.

- Level 0 (Incomplete): Processes are not performed or fail to achieve their purpose.

- Level 1 (Performed): Process purpose is achieved by executing base practices.

- Level 2 (Managed): Processes are planned, monitored, and work products are managed.

- Level 3 (Established): Processes are implemented using a defined, organization-wide standard process.

- Level 4 (Predictable): Processes are executed with predictable outcomes, controlled by metrics.

- Level 5 (Innovating): Processes are continuously optimized based on metrics and innovation.

Example

GIC

- GIC Software Requirements Specification (SWE.1)

- GIC Software Architectural Design (SWE.2)

- GIC Software Detailed Design (SWE.3)

Conclusion

The ASPICE V-model offers a systematic and quality-oriented approach in automotive software development, ranging from requirements definition to final testing and functional safety integration.

Rigorous verification across each development stage and synergy with functional safety standards like ISO 26262 are essential for developing high-quality and safe automotive systems.

Through ASPICE capability levels, organizations can assess process maturity and continuously improve to gain a competitive edge.

References

-

[1] Organisation of ASPICE V-model. Download Scientific Diagram - ResearchGate -

[2] An introduction to ASPICE Model for Automotive Development Jama Software -

[3] Automotive SPICE® Process Assessment Model System Development SIS - UL Solutions -

[4] Automotive Safety and Compliance with ISO 26262 and ASPICE - Inflectra Corporation -

[5] What is ASPICE V Model - YouTube - [6] Automotive SPICE - Wikipedia

-

[8] Automotive SPICE and ISO 26262 in Engineering Lemberg Solutions - [9] SDLC V-Model - Software Engineering - GeeksforGeeks

- [10] ASPICE 101: Everything you need to know about Automotive SPICE - Spyrosoft

- [11] Toward Safer and Smarter Automotives: Unlocking ASPICE, Functional Safety, and Cybersecurity - Blog - L&T Technology Services (LTTS)

- [12] ASPICE vs ISO 26262 – what is the difference? - Spyrosoft